Contact Transducers

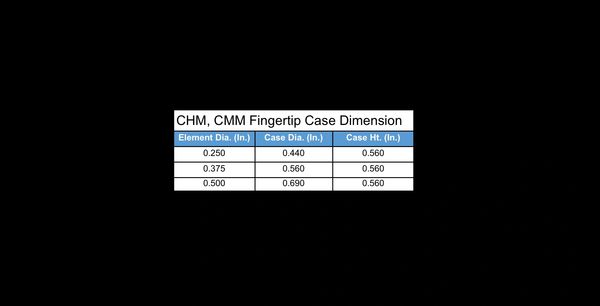

Fingertip Transducers

- Fingertip small case size for accessibility in restricted locations

- Stainless steel case and heavy duty wear plate for rugged durability

- The highest quality piezo ceramic materials for superior performance

- Right angle microdot connector supplied unless otherwise noted, other styles available on request

CHM, CMM Series

CHM is the highest damped (Broad Band) transducer for near surface resolution, thickness gauging and other high resolution applications. DCMM is a general purpose (Medium Band) transducer with high resolution and signal to noise ratio for common materials.

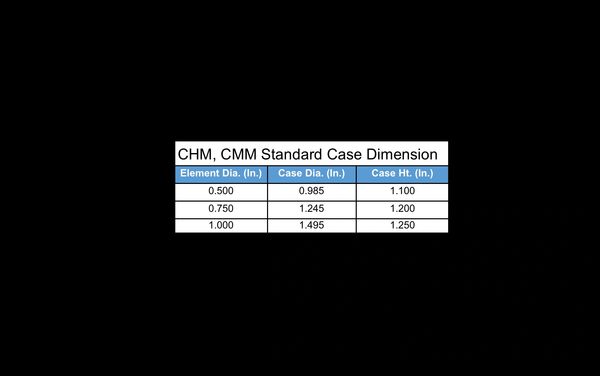

Standard Transducer

- Stainless steel case and heavy duty wear plate for rugged durability

- The highest quality piezo ceramic materials for superior performance

- Convenient molded plastic grip for operator comfort

- Right angle BNC connector (RB) supplied unless otherwise noted, other styles available on request

Connector Options:

RL: Right Angle Lemo

SB: Straight BNC

CHM, CMM Series

CHM is the highest damped (Broad Band) transducer for near surface resolution, thickness gauging and other high resolution applications. CMM is a general purpose (Medium Band) transducer with high resolution and signal to noise ratio for common materials.

PROTECTIVE MEMBRANE TRANSDUCER

- Thickness gauging and flaw detection of pipes, plates, etc.

- Functionally designed case styles to suit each application

- Abrasion resistant replaceable wear caps for longer service life

- Right angle BNC connector (RB) supplied unless otherwise noted

Connector Options:

SB: Straight BNC

RL: Right Angle Lemo

SL: Straight Lemo

PMT series with PM, WC, HD options

PMT Protective membrane transducers are for use where coupling is difficult due to irregular surface conditions. The PM membrane will conform to surface irregularities for better coupling.

WC replaceable wear caps are used when scrubbing of the test material is necessary and greatly extends transducer lifetime.

HD high temperature delay option are available for high temperature testing up to 600° F.

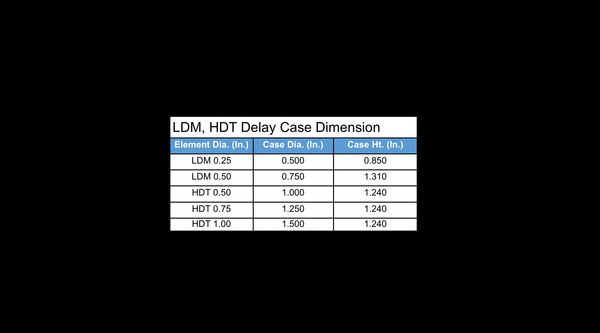

Delay transducers

- Very thin material thickness gauging and near surface flaw detection

- Hot surface thickness gauging and flaw detection of pipes, plates, etc.

- Abrasion resistant delays for longer service life

- Functionally designed case styles to suit each application

- Custom transducers available for continuous contact up to 500° F

- Other custom features available

LDM, HDT Series

LDM is the highest damped (Broad Band) delay transducer for thickness gauging of thin materials, down to .005", and near surface flaw detection. Use LD delays with LDM transducers.

HDT is a high temperature delay transducer with high gain for high temperature applications up to 600° F (15% duty cycle with 10 second maximum contact time). Use HD high temperature delays with HDT transducers.

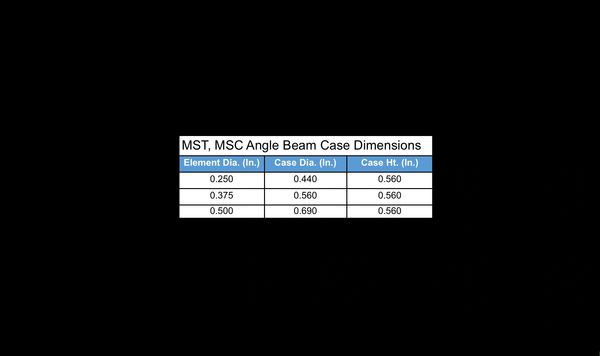

Angle Beam Transducers

Miniature Angle Beam Transducer

- Exceptional resolution, gain, and signal to noise ratio, well suited for inspection of weldments and joints.

- Composite element provides higher damping and wider bandwidth when compared to standard element MST transducer.

- Wedges designed with short index, perfect incidence angle, and low noise

- Tool-free screw-on wedge design allows multiple purpose use for a single transducer

MST, MSC Series

MST miniature shear wave transducers can be used with MSW screw-on style wedges, or MSH high temperature wedges for intermittent contact up to 500 F (15% duty cycle with 10 second maximum contact time).

MSC miniature shear wave composite element screw-on transducers are fully compatible with Megasonic MST series miniature shear wave transducers and use the same MSW and MSH (high temperature) wedges. MSC transducers take advantage of composite element technology for critical applications that require the higher damping than MST series.

Standard Angle Beam Transducer

- Exceptional resolution, gain, and signal to noise ratio, well suited for inspection of weldments and joints.

- Wedges designed with short index, perfect incidence angle. and low noise.

- Removable wedge design allows multi-purpose use for a single transducer.

- Full steel top plate for long transducer lifetime.

- Continuous duty high temperature transducers are available upon request.

- Straight BNC connector (SB) supplied unless otherwise noted

RST, AWS Series

RST standard shear wave angle beam transducers are used with LSW standard wedges or HSW high temperature wedges for up to 900° F (15% duty cycle with maximum 10 second contact time). Cool to room temperature before reuse.

AWS transducers meet AWS structural welding code D1 .1 and are used with LSW .75" x .75" wedges.

Angle Beam Wedge MSW, MSH Series

Angle Beam Wedge LSW, HSW Series

Potted Shearwave Transducers

- For use with all standard flaw detectors

- Primary use in weld inspection and flaw detection

- Small case size for tight quarters inspection

- Small footprint allows testing of non-planar surfaces

- Durable metal case for long lifetime

- Standard right angle microdot and BNC connector with other options available

MSP Series

MSP series potted angle beam transducers are designed for restricted access applications where a separable type transducer may be too large.

Focussed Shearwave Transducers

- For use with all standard flaw detectors

- Specifically engineered for very high gain to allow use where other transducers fail

- Custom focal depth transducers are available

- Durable metal case for long lifetime

- Right angle Lemo connector is standard with other options available

MSF

MSF series angle beam transducers are designed for detecting 1.5 µm micro crack clusters in either pitch catch or pulse echo configuration. Broad bandwidth is standard but an 8 MHz centered narrow bandwidth transducer is an available option.

dual transducers

- Useful for flaw detection, corrosion detection, and thickness gauging by use of the pitch-catch technique.

- Exceptionally suitable for testing pipes from O.D. and I.D.; contoured faces available for better coupling.

- The highest near surface resolution with high signal to noise ratio.

- Special pitch-catch included angles available for optimized performance.

- Stainless steel case and durable delay material for longer service life.

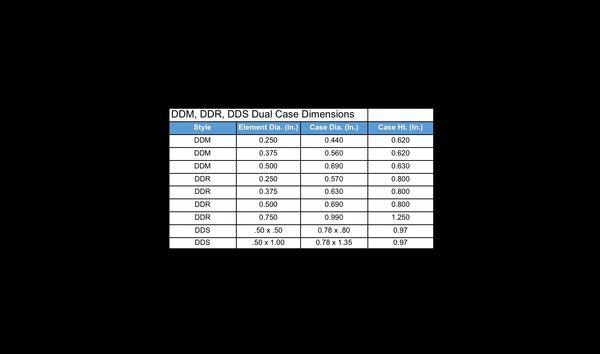

DDM, DDR, DDS, DDH series

DDM & DDR fingertip transducers are for limited access areas. Potted (DDM) and removable (DDR) cable designs are available (microdot connector) .

DDRW finger tip transducers are for 20 dB higher gain and improved high frequency performance.

DDS standard removable delay and cable design transducers are for general purpose applications (microdot or lemo connectors).

DDH Series are removable cable high temperature transducers. Many different types of special transducers are available for all types of applications such as high temperature testing up to 750 F (15% duty cycle with 10 second maximum contact time). Special 1000 F transducers are also available.

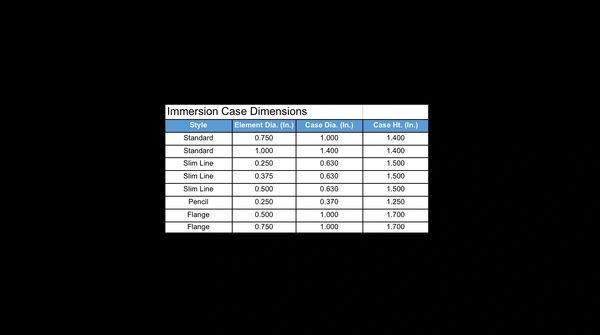

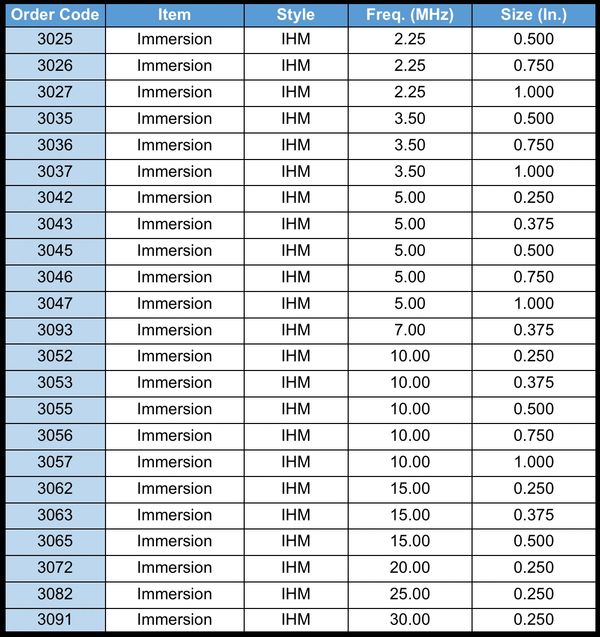

immersion transducers

- Rugged waterproof stain-less steel cases for long service life

- Acoustic impedance matched quarter wave epoxy facings for better gain, resolution, and sensitivity

- Focusing option for improved near surface resolution and increased sensitivity to small discontinuities

- Miniature and custom transducers available for tight quarters inspection or special purposes

IHM Series

IHM transducers are highly damped (Broad Band) for the high resolution applications such as near surface flaw detection. This series can be optimized for thickness gauging applications as well.

IMM, ILT, IPM Series

IMM general purpose transducers (Medium Band) have high signal to noise ratios for high resolution flaw detection in all materials.

ILT transducers are designed with exceptional penetrating power (Narrow Band) for good resolution flaw detection in acoustically lossy materials.

IPM paintbrush style transducers have a wide scan area for rapid inspection. Flatness of the gain envelope is guaranteed to be less than + - 2.0 dB.

Focusing is available when required, specify spherical or cylindrical focusing with focal length.

Case Styles

A: Standard cases for .750" and 1.0" diameter or larger elements (UHF connector)

S: Slim line case for .250", .375", and .500" diameter elements (UHF connector)

P: Pencil case for restricted area, .125" and .250" diameter elements (microdot connector)

K: Right angle case for restricted areas when the use of a wand is not warranted. .250", .375", and .500" diameter elements (UHF connector)

F: Flange case for .250", .375", .500", .750" diameter elements (button or microdot connector)

B: Bore Probe cases for .125", .187" and .250" diameter elements (microdot connector)

Thickness Gauging Transducers

- For thickness gauges or flaw detectors

- Compatible with all thickness gauges

- Used on pipe, plate, or irregular shapes of most metals and non-metals (plastics, glass, etc.)

- Miniature cases for tight quarters inspection

- Low frequency large diameter transducers for coarse grain and attenuative materials

CHM, LDM, M, NID

CHM contact transducers are for thick- ness gauging of relatively smooth flat plates 0.050" thick and up.

LDM delay transducers are for thin material thickness gauging as thin as 0.005".

DDH dual transducers are for thickness and corrosion gauging of pipes from O.D. and I.D. capable of measuring from .030" to 1 O" of steel.

High temperature (up to 950° F) application transducers are available.

NID no interface delay transducers (between NI transducer delay and test material) are for accurate thickness gauging of composites and other plastic materials. Elimination of the delay interface allows near surface resolution.

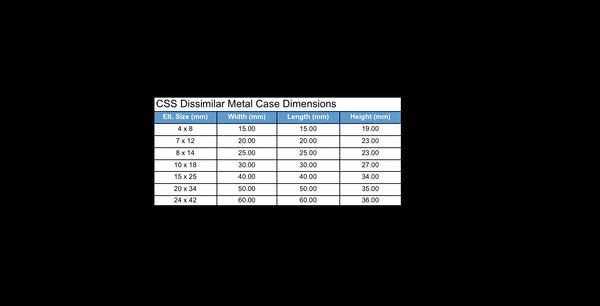

Dissimilar METAL transducers

- Highest signal to noise ratio, exceptional penetrating power, and high resolution

- Rugged stainless steel case construction

- Specify focal depth (FD) or focal sound path (FS) for CSS transducers

- Other angles, frequencies, and sizes are available

- OD and ID contouring available

- Custom transducers including multi-crystal systems available

- Mechanized systems with couplant supply ports available

- Right angle lemo connectors supplied unless otherwise specified

CGS, CSS, MOST Series

CGS single element I.D. creeper transducers are used for flaw detection and sizing, preliminary detection, and less than 15% crack testing.

MOST tandem sizing transducers are for testing 10 to 40 mm wall thickness pipes, covering 10% to 90% of wall thickness.

CSS are ultra-high gain dissimilar metal weldment and cast stainless steel testing dual angle beam transducers.

Order Code: 2347-2393

TOFD Transducers & Wedges

TOFD transducer series is specifically designed for TOFD applications.

TOFD transducers are damped to 3 half cycles with the highest possible gain.

ATOFW & ATOFB automated wedges improve gain by 10 to 25 dB compared to ATOF wedges for frequencies above 5.0 MHz. This will extend the useful frequency range of transducers up to 15 MHz.

TOFD Transducers

ATOF wedges are standard time of flight wedges for automated testing.

ATOFW wedges are automated time of flight wedges with improved high frequency performance.

ATOFB & ATOFV automated wedges can be used for temperatures as high as 650°F continuous and 900°F intermittent.

Automated scanner wedges include one pair of side mounting holes 0.080” diameter x 0.125” deep. An irrigation channel and couplant port are also included. For transducers 0.500” in diameter the wedge dimensions are 1.000” w x 0.700” h, for 0.250” and 0.375” diameter transducers the dimensions are 0.800” w x 0.650” h. Wedge lengths vary with angle.

Bolt Gauge Transducers

- The transducers are built with a stainless steel case and tough alumina wear plate for durability.

- Rare earth hold down magnets provide secure and repeatable contact.

- High performance BGT transducers have high gain, high resolution, and high signal to noise ratio.

- Performance is reliable and consistent from transducer to transducer.

- BGT transducers are compatible with most bolt tension meters.

- High temperature (400 °F continuous duty) versions are available.

BGT series transducers are special application magnetic hold down transducers for use in bolt tension measurements.

X-Y Manuipulators

Megasonics is proud to introduce our most recently designed X-Y manipulator. Our stainless steel design ensures excellent durability and corrosion resistance unlike most other manipulator designs. Yet, at only 11 ounces, our manipulator is comparable in weight to other manipulators executed in plastic or aluminum. The design is both compact and precise with no backlash. Overall dimensions exclusive of connectors are 3.14” L x 1.82” W x 1.13” D.

Stainless steel X-Y manipulator. Order code: 5191

Stainless steel X-Y manipulator with angle indicator, two axes. Order code: 5192

SIZING CALIBRATION BLOCKS

SDH

SDH Side drilled hole calibration blocks. One inch block with 0.062" diameter thru side drilled holes covering 0.100" to 0.900" depth and two inch block with 0.125" diameter thru side drilled holes covering 0.200" to 1.800" depth.

EDM

EDM Electron discharge machined notched calibration blocks. One inch block with 0.032" x 1.000" notches covering 0.100" to 0.900" depth and two inch block with 0.032" x 1.000" notches covering 0.200" to 1.800" depth.

- Side drilled hole or EDM notched blocks for crack depth sizing.

- 1018 carbon steel or 304 stainless steel material. Other materials are available on request.

- Block dimensions, hole diameters, and notch depths are accurate to within +/- 0.005".

- All materials are ultrasonically tested to be free of defects.

- Solid oak carrying case.

- Custom designed blocks are available for a reasonable price

SPECIAL TRANSDUCERS

Bar and Tube Transducers

Bar and Tube Transducers

No standard line of products can anticipate every customer need. Your special applications are just as important to us as your standard application. Our facilities are capable of handling your most difficult requirements. Our staff has over 47 years of experience in the ultrasound industry and can work closely with you to provide the right transducer for the right job.

Bar and Tube Transducers

Bar and Tube Transducers

Bar and Tube Transducers

Bar and Tube Inspection Transducers for wall thickness testing and axial and longitudinal flaw detection.

Hydrogen Damage Transducer Assembly

Hydrogen Damage Transducer Assembly

Hydrogen Damage Transducer Assembly

Hydrogen Damage Transducer Assembly for detecting hydrogen damage or cracks in boiler tubes using pitch-catch transducers.

Bore Probes (Immersion)

Hydrogen Damage Transducer Assembly

Hydrogen Damage Transducer Assembly

Bore Probes (Immersion) in side looking and 90 F reflected configurations for use in I.D. side tube inspection and other applications involving restricted access.

Billet Inspection Transducer

Extremely Small Diameter Transducers

Extremely Small Diameter Transducers

Billet Inspection Transducers for testing stock such as titanium, waspalloy, and inconel bars and billets up to 16" diameter.

Extremely Small Diameter Transducers

Extremely Small Diameter Transducers

Extremely Small Diameter Transducers

Extremely Small Diameter Transducers for inspection of restricted areas. Straight beam contact or immersion transducers with case diameters as small as 0.120" are available.

Bore Probe (Contact)

Extremely Small Diameter Transducers

Magnetically Attached Transducers

Bore Probe (Contact) with spring loaded angle beam contact transducers for detection of cracks in pipes and studs.

Magnetically Attached Transducers

Spring Loaded Positioning Addaptor

Magnetically Attached Transducers

Magnetically Attached Transducers for bolt elongation measurements during bolt torqueing or for transducer positioning during long term testing.

Captive Water Column Transducers

Spring Loaded Positioning Addaptor

Spring Loaded Positioning Addaptor

Captive Water Column Transducer containing an internal water column behind a replaceable elastic membrane. The flexible membrane maintains good contact for inspection of nonplanar surfaces.

Spring Loaded Positioning Addaptor

Spring Loaded Positioning Addaptor

Spring Loaded Positioning Addaptor

Spring Loaded Positioning Adaptor which attaches to transducers to provide consistent positioning of the transducer on cylindrical surfaces.

Automated Scanner Wedges

Swivel-Head Transducer Assembly

Automated Scanner Transducers

Automated Scanner Wedges in various standard and custom shapes for use by automated scanning systems.

Automated Scanner Transducers

Swivel-Head Transducer Assembly

Automated Scanner Transducers

Automated Scanner Transducers including standard and custom configurations to meet the requirements of all automated test systems.

Swivel-Head Transducer Assembly

Swivel-Head Transducer Assembly

Handheld Bubbler Transducer Assembly

Swivel-Head Transducer Assembly which provides flexible solutions for the most difficult access problems.

Handheld Bubbler Transducer Assembly

Handheld Bubbler Transducer Assembly

Handheld Bubbler Transducer Assembly consisting of a 20 MHz transducer and detachable bubbler cone. This configuration provides high resolution for thin materials testing and a small footprint for ease of access.

Special Transducers not pictured:

Special Transducers not pictured:

- AXLE TESTER

- VELOCITY TRANSDUCER

- WATER DELAY CONTACT TRANSDUCER SPOT WELD DELAY TRANSDUCER

- SPRING LOADED TRANSDUCER

ASK FOR DATA SHEET/BROCHURE ON EACH SPECIAL TRANSDUCER

Transducer Accessories

Cables

Optional heavy duty long lasting cables are available for an extra cost

Cables

Search Tubes and Adapters

UST stainless steel immersion search tubes are O.D. Ground to .745" diameter for use with all immersion transducers

Search Tubes and Adapters

High Temperature Couplant

At elevated temperature, the HTC couplant maintains optimum viscosity for ease of testing

High Temperature Couplant

Ultrasonic test blocks

Megasonics offers ASME, AWS, IIW, and AST ultrasonic reference blocks made of ultrasonically inspected steel, aluminum, and stainless steel. Steel blocks are nickel plated and aluminum blocks are anodized. All blocks are completely ground for extreme accuracy. Other material blocks are quoted upon request. All prices include cases except for single ASTM blocks.

- Type DC: For distance calibration of shearwave transducers. AWS specification. Order Code 5301

- Type SC: For sensitivity calibration of shearwave transducers. AWS specification. Order Code 5304

- Type DSC: for distance and sensitivity calibration of shearwave transducers. AWS specification. Order Code 5307

- ASW Resolution Block: For evaluation of the resolution capability of shearwave transducer. Order Code 5310

- Miniature Angle Beam: For general angle beam calibration where compact size and weight are important. Point of incidence, refracted angle, and distance calibrations can be determined. Order Code 5313

- Step Blocks: For thickness and linearity calibration. Available in four step version, .250", .500", .750", and 1.000", (Order Code 5316) or five step version, .100", .200", .300", 400", and .500". Order Code 5319

- Miniature Resolution Block: For evaluation and calibration of high resolution ultrasonic transducers and test instruments. Order Code 5322

- IIW Block Type I: For calibration of shearwave transducers, distance and sensitivity of instruments, and evaluation of resolution capability of transducers. Order Code 5325

- IIW Block Type II: Modified IIW type I block. Addition of a 2 0" radius x .250" deep cut-out and three side-drilled holes for resolution and sensitivity calibration. Order Code 5328

- 30 FBH Resolution Block: For evaluation of resolution capability of transducers, calibration of instrument, and determination of flaw sizes and depths. 10 holes each of 3/64", 5/64", and 8/64" dia. FBH at .050" to 1.250" distances. Order Code 5331

- ASME Reference Plate N-625: For checking sensitivity and performance of instruments and transducers. Longitudinal, shear, and surface waves can be calibrated. Order Code 5334

- ASTM Area/Amplitude Set: The following 8 blocks: 1-0300, 2-0300,3-0300,4-0300,5-0300, 6-0300, 7-0300, and 8-0300. Order Code 5337

- ASTM Distance/Area Amplitude Set: The following 10 blocks: 3-0300, 5-0300, 8-0300, 5-0012, 5-0025, 5-0050, 5-0075, 5-0150, 5-0600 and 8-0600. Order Code 5340

- ASTM Distance/Amplitude Set: 19 blocks with the same size flat bottom hole. Specify 3/64" or 5/64" dia. The metal distances of the blocks are: 1/16, 1/8, ¼, 3/8, ½, 5/8, ¾, 7/8, 1, 1¼, 1 ¾, 2 ¼,2 ¾, 3 ¼, 3 ¾, 4 ¼, 4 ¾, 5 ¼, 5 ¾ inches

Step Block